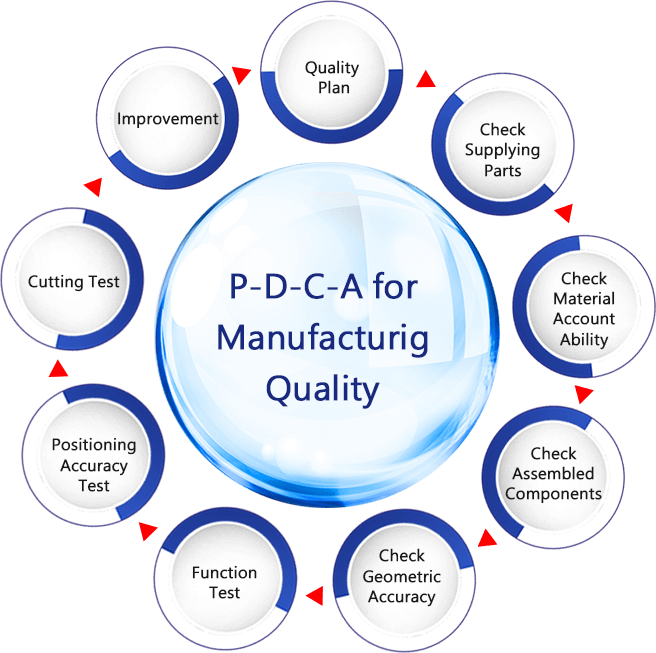

Total Quality Management

Quality ASSURANCE

Spindle Vibration Analysis Every spindle goes through a precision vibration analysis.

The faulty equipment offline before a hazardous condition occurs. As a result, fewer unexpected spindle failures, helping to prevent production stoppages that cut into the bottom line.

The faulty equipment offline before a hazardous condition occurs. As a result, fewer unexpected spindle failures, helping to prevent production stoppages that cut into the bottom line.

Laser Calibration

- Increase machine accuracy and repeatability

- Lower maintenance and production costs

- educe scrap, rework, and part inspection costs

- Develop predictive maintenance programs on machine

- wear patterns

- Reduce catastrophic breakdowns

- Increase equipment life

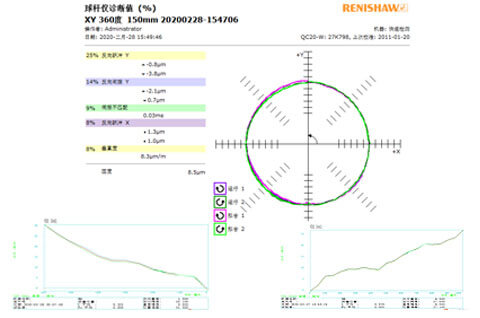

Ball Bar Analysis Ballbar analysis is performed on every ECOM machine to determine the machine's mechanical and servo performance.

The ballbar analysis allows error sources such as backlash, reversal spikes, lateral play, squareness, straightness, scaling mismatch, and servo tuning discrepancies to be pinpointed.

It quantified and reduced or eliminated, resulting in better accuracy in circular interpolation.

The ballbar analysis allows error sources such as backlash, reversal spikes, lateral play, squareness, straightness, scaling mismatch, and servo tuning discrepancies to be pinpointed.

It quantified and reduced or eliminated, resulting in better accuracy in circular interpolation.

Data Analysis Perform different testing systems for a comprehensive and rapid check of the machine geometry. The diagnosis may determine the contour motion error at the preliminary stages.

The test report can use the result as a footprint or reference so that the machine can monitor the contouring accuracy over the medium- and long-term periods.

The test report can use the result as a footprint or reference so that the machine can monitor the contouring accuracy over the medium- and long-term periods.

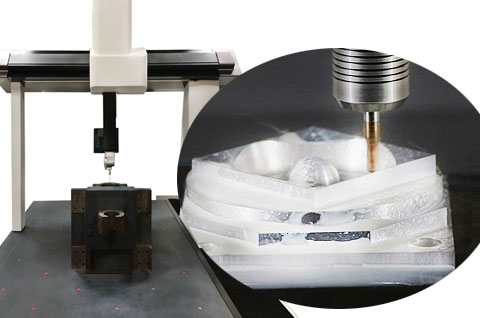

Coordinate Measuring Testing (CMT) As manufacturing becomes more refined and parts are made more complex, the need for accurate and precise measurement technologies becomes increasingly mandatory. Every ECOM machine performs a test cut of a workpiece then analyzed by our in-house Coordinate Measuring Machine.

Cutting Test Every ECOM machines perform various tests, including a workpiece test cut for measuring position accuracy and repeatability accuracy by in-house Coordinate Measuring Device (Hexagon Metrology).

Cutting Test Every ECOM machines perform various tests, including a workpiece test cut for measuring position accuracy and repeatability accuracy by in-house Coordinate Measuring Device (Hexagon Metrology).

Quality Assurance

Consistently high quality. The right product at the right time.

Reliability

Delivers the correct product on time. Goods and services work as described.

Communication

Easy to communicate with suppliers.

Capacity

Ability to manage increased volumes of supply in a short notice.

Financial stability

The financial aspects of the supplier also taken into consideration.