Specifications

GT-3662

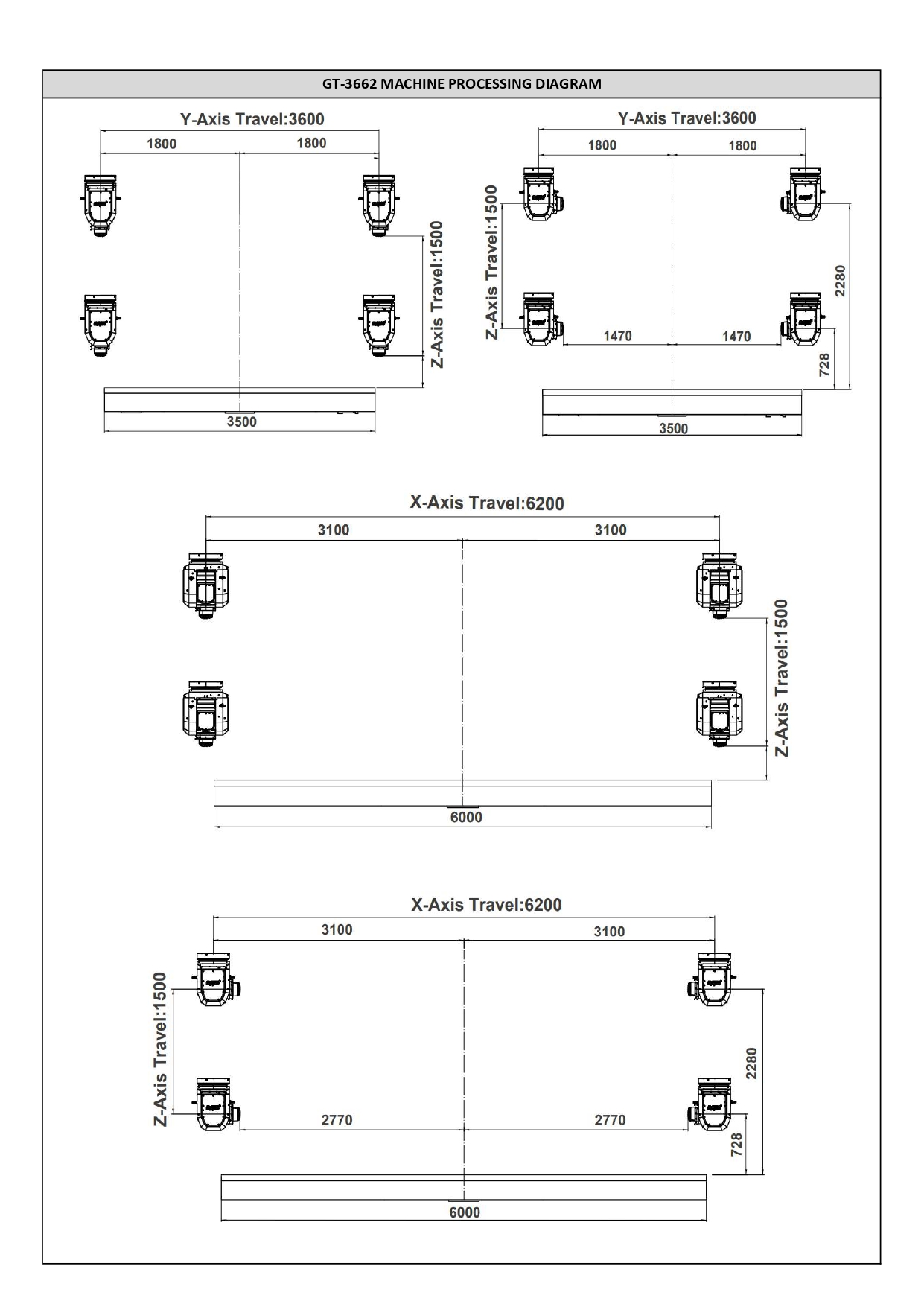

| Travel | X - Axis Travel | 6200mm | |

|---|---|---|---|

| Y - Axis Travel | 3600mm | ||

| Z - Axis Travel | 1500mm | ||

| Dolumn Distance | 4500mm | ||

| Working Space | 3600X6200X1900mm | ||

| Spindle Nose To Table | 400-1900mm | ||

| Table | Table Size | 6000x3500mm | |

| T - Slot | 32mmx250mmx18T | ||

| Maximum Table Load | 8000kg / M² | ||

| Spindle | Spindle Taper | HSK-63A | |

| Type Of Driving | Built-in Type | ||

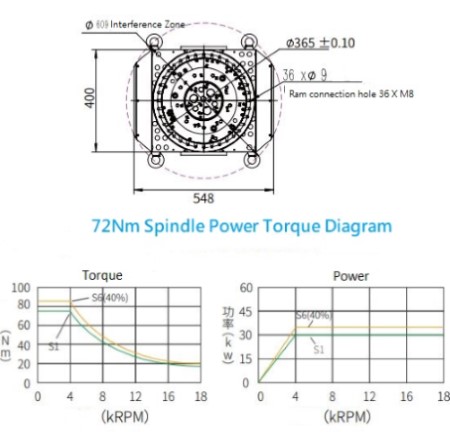

| Spindle speed | 18000rpm | ||

| Feed Rate | Rapid traverse(X.Y.Z)axis | X:12 Y:12 Z:12(m/min) | |

| Cutting feedrate | 1~8000(mm/min) | ||

| Type Of Driving | X Axis Type Of Driving | Gear Ratio (1:20) | |

| Y Axis Type Of Driving | Gear Ratio (1:3) | ||

| Z Axis Type Of Driving | Direct Drive | ||

| Automatic tool changer | Max.tool Diameter | Ø78 (Full) ~ Ø150mm (Empty) | |

| Max.tool Length | 300mm | ||

| Max.tool Weight | 8kg | ||

| Motors | SIEMENS ONE | ||

| Spindle Motor | 30kW / 72Nm | ||

| X Axis Servo Motor | 5.5kW(36Nm) | ||

| Y Axis Servo Motor | 7.7kW(48Nm) | ||

| Z Axis Servo Motor | 7.7kW(48Nm)BS | ||

| Machine Accuracy | Positioning Accuracy (JIS) | ±0.01/300;±0.02/Full travel | |

| Repeat Poitioning Accuracy (JIS) | ±0.005mm | ||

| Others | Coolant tank capacity (pump) | 300L (1000W) | |

| Hydraulic fluid tank capacity | 160L (7500W) | ||

| Pneumatic supply | ≧ 6.5Kg/c㎡ | ||

| Floor Space Measurement | 10320X6280X4900mm | ||

| Machine weight (approximate) | 60000KG | ||

Above specification are subject to change without prior notice.

Standard Accessories

| SIEMENS ONE controller 19" LCD |

| Built-in Type, 18,000rpm |

| Leveling screws with blocks |

| Tool box |

| Air blast through spindle |

| Work lamp |

| Semi-Enclosed Splash Guard |

| Unclamping pedal |

| Three color light |

| Auto power off |

| Auto lubrication system |

| USB interface |

| Portable Hand Wheel (MPG) |

| Spindle coolant system |

| Heat exchanger for control cabinet |

| Pressure system(not included air pressure source & air pressure tube) |

| High pressure water & air gun |

| Chain Type Chip Conveyor |

| System operation and procedures manual |

| Machine operation Manual |

| HSK63A Arm Type ATC(24T) |

| Coolant through spindle(30Bar) |

| X.Y.Z. A.C Optical scale |

Optional Accessories

| HSK-A63 ARM Type 30 position |

| HSK-A63 Chain Type 40 position |

| HSK-A63 Pocket Type 60 position |

| Heidenhain Optical Linear Scales XYZ |

| Renishaw NC4 |

| Renishaw OMP60 |

| CE Mark (Safety Door Switches) |