Specifications

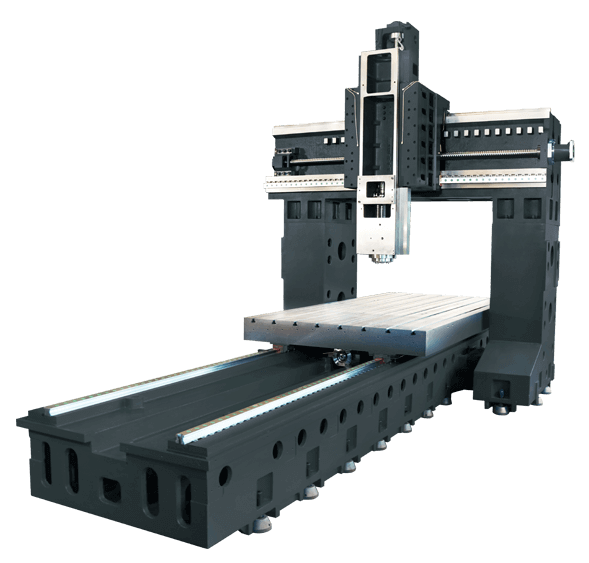

DMCB-2750

| Travel | X - Axis Travel | 5000mm | |

|---|---|---|---|

| Y - Axis Travel | 2700mm | ||

| Z - Axis Travel | 1000mm | ||

| Distance between column | 2700mm | ||

| Working Space | 2700X5000X1280mm | ||

| Spindle Nose To Table | 280-1280mm | ||

| Table | Table Size | 2300x5000mm | |

| T - Slot | 28mmx200mmx11T | ||

| Maximum Table Load | 15000kg | ||

| Spindle | Spindle taper-D mm | BT50-200 | |

| Type Of Driving | Belt Type | ||

| Spindle speed | 6000rpm | ||

| Feed Rate | Rapid traverse(X.Y.Z)axis | X:10 Y:10 Z:10(m/min) | |

| Cutting feedrate | 6000(mm/min) | ||

| Type Of Driving | X Axis Type Of Driving | Planetary gear drive (4:1) | |

| Y Axis Type Of Driving | Planetary gear drive (3:1) | ||

| Z Axis Type Of Driving | Direct type drive | ||

| Automatic tool changer | Max.tool length | 350mm | |

| Max.tool weight | 15kg | ||

| Max.tool dia.-(Full tools) | Ø110mm | ||

| Max.tool dia.-(W/O Adjacent tool) | Ø200mm | ||

| Motors | 0iMF-α | ||

| Spindle Motor | 15/18.5kW(249Nm) | ||

| X Axis Servo Motor | 9kW(53Nm) | ||

| Y Axis Servo Motor | 6kW(38Nm) | ||

| Z Axis Servo Motor | 7kW(30Nm)BS | ||

| Machine Accuracy | Positioning Accuracy (JIS) | ±0.005/300;±0.015/Full travel | |

| Repeat Poitioning Accuracy (JIS) | ±0.003mm | ||

| Others | Coolant tank capacity (pump) | 300L (1000W) | |

| Hydraulic fluid tank capacity | 160L (7.5KW) | ||

| Pneumatic supply | ≧ 6.5Kg/c㎡ | ||

| Floor Space Measurement | 12400X5500X4800mm | ||

| Machine weight (approximate) | 48000KG | ||

Above specification are subject to change without prior notice.

Standard Accessories

| Fanuc 0i-MFa1 controller 10.4" LCD |

| Belt-type 6,000rpm |

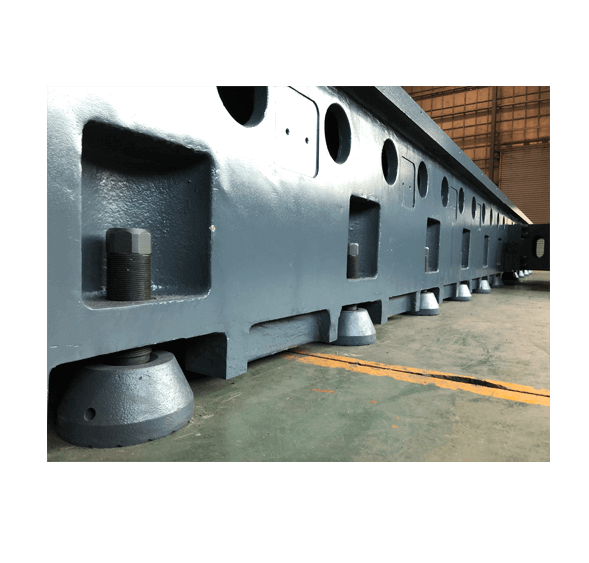

| Leveling screws with blocks |

| Tool box |

| Air blast through spindle |

| Work lamp |

| Unclamping pedal |

| Three color light |

| Auto power off |

| Auto lubrication system |

| Rigid tapping |

| CF card interface |

| Portable Hand Wheel (MPG) |

| Spindle coolant system |

| Heat exchanger for control cabinet |

| Pressure system(not included air pressure source & air pressure tube) |

| High pressure water & air gun |

| Screw Type Chip Conveyor |

| Chain Type Chip Conveyor + Cart |

| System operation and procedures manual |

| Machine operation Manual |

Optional Accessories

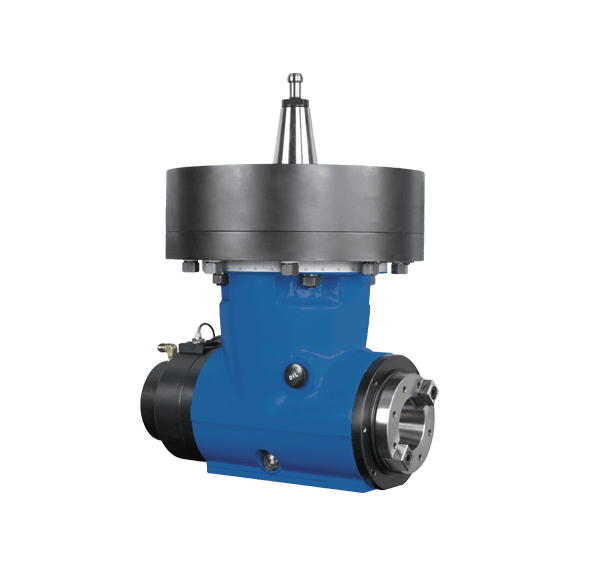

| 90∘ angular milling head (Manual) |

| 90∘ angular milling head (Semi-automatic) |

| 90∘ angular milling head (Automatic) |

| BT-50 Arm type ATC(24T) |

| BT-50 Arm type ATC(30T) |

| BT-50 Chain type ATC(40T) |

| BT-50 Chain type ATC(60T) |

| Column raised: 200mm /400mm |

| Tool length measurement system |

| Coolant through spindle (24Bar/50Bar) |

| Disk type oil-water speartor |

| Auto Door |

| X/Y/Z Optical scale |

| Workpiece measurement system |

| Full splash guard |

| CE standard |

| AICC2 (Preview blocks max.200) |

| Data Server memory capacity 1G |

| Oil Must Collector |

| Atomizing device for spindle oil mist cutting |

| External interface for cutting oil mist to tool holder |

| Air conditioner |